Mochini oa ho Embossing

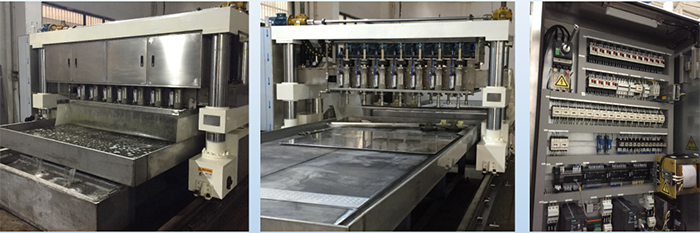

YH1600 Automatic Embossing/Stamping Machine

Tlhaloso

Mohala ona o entsoe ka 1600T 4-Column Press, Front and Back Feeding Unit hammoho le Pressing Dies.E loketse High Tonnage Pressing ea Antikaid Plate, Anti Slippery Plate, Safety Tread.Mochini o Khethetsoe ka Mocheso o Khethehileng le Bead Blasted, Ka hona, Khatello ea Ka hare e tlositsoe 'me Surface e Toughened, e ka netefatsang ho nepahala ha nako e telele ho sebetsa le ho lelefatsa nako ea bophelo ea mochine ka boeona le oa ho shoa.

Mochini ona o sebelisoa haholo-holo ho etsa lipampiri tse khabisoang, poleiti ea anti-sliding.Frame e entsoe ka tšepe e boima e cheselitsoeng, khatello e lokollotsoe.1600 ton 4 mofuta oa kholomo ea Hydraulic Press e tla laoloa ke sistimi ea Servo.Dies Auto Move In-Out bakeng sa ho nkela sebaka habonolo.Ts'ebetso ea ho tsitsa e 'nile ea nkoa ha ho etsoa moralo oa die, e leng se ka tiisang ho bata ha poleiti.PLC hammoho le HMI ke bakeng sa ts'ebetso e bonolo le ho e lokisa.Likarolo tsa enjene, tse fokotsang metsi le li-hydraulic li tla sebelisoa.

Mekhahlelo ea mantlha ea tekheniki

| Kaho | Koala Mofuta | Hlokomela | ||

| Matla ka lebitso | KN | 16000 | ||

| Botenya ba Leqephe le Phahameng | mm | 6 | ||

| Boholo ba Leqephe la Max | mm | 1500X6000 | ||

| Fepa Precision | mm | ±0.2 | ||

| Ho Pheta Positioning Precision of Origin | mm | ±0.2 | ||

| Max Stamping Frequency | Linako/Metsotso | 10 | ||

| Min Stamping Frequency | Linako/Metsotso | 6 | ||

| Khatello e sebetsang ea Hydraulic | MPa | 20 | ||

| Kakaretso ea Matla | KW | 100 | ||

| Bophahamo ba Mohlala | mm | 1.2-1.3 | ||

| Workable Raw Material | Stainless Steel ea 200/300/400 Series | |||

| Boima ba Mochini | T | 40 | ||

| Tekanyo ea Mochini | mm | 13500×3300×5300 | ||

Lethathamo la Likarolo tse ka Sehloohong

| Che. | Likaroloana | Etsa | Hlokomela |

| 1 | Ea fepang | HT | |

| 2 | 4-Column Press | Yangli | |

| 3 | Shoa | HT | |

| 4 | Likarolo tsa Pneumatic | Airtec | |

| 6 | Linear Track | Hiwin kapa ABBA | |

| 7 | Servo Motor Drive | Xinjie | |

| 8 | Skrine | Weinview | |

| 9 | PLC | Siemens | |

| 9 | Sistimi ea Motlakase | HT | |

| 10 | Mojule | Siemens | |

| 11 | Lisebelisoa tsa Motlakase | (1)Switch: Taiwan Mingwei (2) Proximity Switch, Relay: Omron | |

| 12 | Mekhahlelo e meraro ea Asynchronous Motor | Letšoao le tummeng la Lehae | |

| 13 | Bearing | NSK | |

| 14 | Likarolo tsa Hydraulic |

Phano ea Phano

| No | Lihlahisoa | Lintlha | Yuniti | Theko | Q'ty | Hlokomela |

| 1 | Ea fepang | Beha | 1 | |||

| 2 | Tobetsa | Beha | 1 | |||

| 3 | Shoa | Beha | 1 | Joalo ka Mohlala | ||

| 4 | Lisebelisoa | Beha | 1 | |||

| 3 | Lisebelisoa tse Khethehileng | No | ||||

| 4 | Tlhomamiso le Komisi | Ho kenya le Komisi ea mahala | ||||

| 5 | Koetliso | Koetliso ea mahala | ||||

| 6 | Bukana | Diski | ||||

Likarolo tsa Mochini

- Matla a Maholo a Khatello, a Sebetsa ka Sekhahla se Seholo

- Automatic Die Moving in and Moving Out Function, ho bonolo haholo ho e fetola Dies.Mefuta e mengata e fapaneng e ka etsoa ho latela tlhoko ea Bareki.

- Sistimi ea Phepelo e Iketsetsang, Boemo ba Auto ho Shoela tlase, 'me e Tsoa ka mor'a ho hatakela.

Matla a motho a hlokahala feela ho tsamaisa lipampiri ho Tafole ea Roller le ho Tlisa Lipampiri ka mor'a ho hatakela.Ho hlokahala opareitara e le 'ngoe feela.

- The die e na le Leveling and Re-Shaping Function, Flatness of Sheets e ka netefatsoa ka mor'a ho Tenta.

Sebaka sa Moreki

Phepelo ea Moea: 0.6Mpa, 1 M3/Mots, Moea o Hatelitsoeng o Omileng le o Hloekileng

Phepelo ea Matla: 415V, 50Hz, Voltage Fluctuation: -10%-+10%

Potoloho ea Mocheso: 0°C – +40°C

Mongobo o Potolohileng: Mongobo o Batlang: 20-80%RH (Ha ho Condensation)

Mahala ho Mohloli o Matla oa Vibration le Tšitiso ea Electro-Magnetic.

E lokolohile ho Lerōle, Moea o Kotsi le Moeeng o Etching

Motheo o lokela ho etsoa ho latela Mothalo oa Motheo ho tsoa ho Mofani.

Lipampiri tse otlolohileng le tse bataletseng tsa S/S.

Opereishene e tsitsitseng le e rutehileng

Kenyelletso ea Khampani

Nalane ea rona:

Setsebi sa Ho Sila ka Lebanta la Lebanta la Flat Abrasives: Sepheo sena se re tataisa ho boloka lipatlisiso mabapi le ho sila le ho bentša tšepe ka sebaka sa li-abrasives tse tlotsitsoeng ho tloha ka bo-1990.

Ka 2005 re ile ra qala ho rala, ho etsa le ho kopanya mechine e silang ea mabanta a abrasive bakeng sa tšepe.Ka keketseho e tsoelang pele ea khoebo le phetoho ea sebopeho sa ba nang le kabelo,

ka 2015 WUXI Zhongshuo Precision Machinery Co., Ltd e thehiloe.

Khampani ea rona:

Re khamphani e laoloang ke beng ba boholo bo bohareng.Khamphani e toropong ea Wuxi, Profinseng ea Jiangsu.Motse-moholo o ngolisitsoeng ke li-RMB tse limilione tse 8.Sebaka sa kaho se feta 7000 m2.Palo eohle ea basebetsi ke 52, ho kenyelletsa le moenjiniere a le mong oa boemo ba Patlisiso, baenjiniere ba 2 ba phahameng le baenjiniere ba 5.Re na le litsebi tsa ho rala, ho etsa thepa, ho kopanya, ho kenya, ho laela le sehlopha sa litšebeletso tsa thekiso.

Lihlahisoa tsa rona

Re hlahisa mochini o pharalletseng oa ho sila le oa ho bentša, mochini oa borashe, mochini o tlatsang seipone, mochini o qetang ho sisinyeha, mochini o hatisang bakeng sa tšepe ea tšepe le lakane, ho kenyelletsa le karolo ea ho kena le ho tsoa ea CGL (Coil to Coil Repairing Grinding Line for Steel Maker) le CPL (Coil). ho Coil Polishing Line bakeng sa Setsi sa Tšebeletso), ke hore Unwinder, Rewinder, Loading Car, Pinch Roll, Flattener, Crop Shear, Coolant Filtration le Recycling system, Washing and Drying system, Mist Collector, Fire Fighting system.Re boetse re fana ka sesebelisoa sa Loading se nang le Vacuum Cups Group bakeng sa Sheet to Sheet Grinding Lin

Bareki ba rona:

Lethathamo la rona la litšupiso ho kenyelletsa Tisco Daming, Wuxi Puxin, Zhejiang Bohai le bareki ba bang ba tsebahalang ba China.Re ile ra romella lihlahisoa tsa rona naheng ea Europe joalo ka Italy, Turkey ka Setifikeiti sa CE.Re boetse re fana ka grinder ea ho lokisa lebanta ho moetsi oa China ea fanang ka thepa ho Aircraft and Nuclear In.

Setifikeiti sa rona

Merero

Ho theha boleng ho moreki ke sepheo sa rona sa kamehla.Khotsofalo ea hau ke matla a tlhahiso ea rona e tsoelang pele.

CPL-Coil to Coil Polishing Line bakeng sa Setsi sa Tšebeletso sa Stainless Steel

CLIENT:浦新金属

CPL e sebelisoa haholo-holo bakeng sa ho tlosoa ha mefokolo e nyenyane ho batang ho roala SS coil ka metsi, fumana ho qeta ho khabisa, ke hore No.3, No.4, HL, SB & Duplo.Pholiso e ka ba emulsion kapa oli ea diminerale.Sistimi ea tlhoekiso e pholileng le ea ho e sebelisa hape e bohlokoa moleng o felletseng.ZS CPL e etselitsoe bakeng sa khola e batang ho sebetsa ho tloha ho 100 ho isa ho 1600 mm bophara le botenya bo pakeng tsa 0.4 ho isa ho 3.0 mm.WUXI ZS e boetse e fana ka CPL e omileng.Cork lebanta e tla sebelisoa ho fumana qetello e tšoanang le ea Scotch-Brite finishing (SB), lebelo la ho fepa la CPL e omileng e ka ba 50m / min kapa ho feta.

SPL-Sheet to Sheet Polishing Line(Mofuta o Metsi)

CLIENT:太钢大明

Mochini oa ho Sila oa Sheet to Sheet (Mofuta oa Metsi) o sebelisa Oli ea ho Sila kapa Emulsion joalo ka Media ho fihlela phello e ntle le e benyang ea ho sila ho lishiti tsa tšepe tse chesang kapa tse batang kapa likhoele.Mochini o etselitsoe ho fumana Finishing No.3 (Coarse Finishing, Abrasive Grain From G60 ho G150) kapa No.4 (Fine Finishing, Most Popular, abrasive grain ho tloha G180 Kapa holimo) le HL Finishing (Hairline Finishing, Characterized by Smooth le mola o molelele).ZSSPL e etselitsoe ho bataho sila letlakaho sebetsa ho tloha600 ho2200 mm bophara le botenya pakeng tsa 0.4 ho 3.0 mm.

PGL-Grinding Polishing Line for Heavy Plate

CLIENT:西部金属

Full Automatic Grinding and polishing Line e sebelisoa haholo-holo bakeng sa ho tlosa bofokoli ho tloha ho hot rolling, pickling & annealing process le residual scale, le ho finyella botenya le boima bo batloang.Pholiso e ka ba emulsion kapa oli ea diminerale.Sistimi ea tlhoekiso e pholileng le ea ho e sebelisa hape e bohlokoa moleng o felletseng.ZSPGLe etselitsoe ho sebetsana le poleiti e boima e chesang ho tloha ho 600 ho isa ho 2200 mm bophara le botenya bo pakeng tsa 1.0 ho isa ho 30 mm.WUXI ZS e boetse e fana ka PGL e omileng.

Seipone Finishing(8K) Machine bakeng sa Stainless Steel Plate

CLIENT:新华医疗

Monyetla oa WUXI 25 Seipone Finishing Machine bakeng sa Stainless Steel Coil le Sheet.Lihlooho tse hlakileng tsa sehlopha ka seng li ka ikemela kapa ka kakaretso lifted up and down .Refiling tsa motsoako oa ho bentša ho qoba bokaholimo bo ka tlas'a disc ea polishing fumana burnt.Tšepe e sa hloekang e entsoeng .Anti corrosion le nako e telelebophelo.Motsamao o boreleli o boreleli ka tataiso ea mola.

Seipone Finishing Machine bakeng sa Cold Rolling Coil le Sheet

CLIENT:MINOX(INDIA)

Mofuta oa pinch roll.E sebetsa resin bonded grinding lebili, Scotch-Brite disc, polishing compound comprising of 5% Al2O3 + 5% nitric acid + 90% metsi ho ntlafatsa holim'a roughness kgato ka kgato, qetellong bartolomeo seipone finishing ka fumanoa (8K).

Sesebelisoa sa ho Laola/Ho laolla se nang le Sehlopha sa Vacuum Cup

CLIENT:博海金属

E na le foreimi ea gantry e entsoeng ka welded, carbon steel le tekanyo e loketseng ho tšehetsa khatello ea kelello ea ho sebetsa.Sesebediswa se na le dihlopha tse latelang: Yuniti ya ho fetolela, Karolo ya ho phahamisa, Yuniti ya Vacuum pick up.

Karolo ea phetolelo e tataisoa ke tataiso ea liner, e tsamaisoang ke servo motor ka gear le pinion.Karolo ea ho phahamisa e tataisoang ke tataiso ea liner, e tsamaisoang ke piston ea moea.Pick-up unit e entsoe ka li-bars tse 3 tse fetolehang tse nang le linoelo tse 18, bar e maemong a tsitsitseng empa kopi e 'ngoe le e' ngoe e monyang e khona ho tsamaea ka bolelele, opareitara e khona ho lokolla sesebelisoa, ho lokisa boemo ba kopi ea ho monya, ho notlela hape ho lokisa habonolo.

Komiki e 'ngoe le e' ngoe ea ho monya e hokahane le phaephe ea moea ea motho ka mong ho netefatsa ts'ebetso e bonolo ea sistimi, kopi e 'ngoe le e' ngoe ea ho monya e hokahantsoe le sebaka sa selemo ho netefatsa sebaka se lekaneng sa ho buffer pakeng tsa linoelo le karolo ea mosebetsi.

Laminator e Ikemetseng bakeng sa Tšireletso ea Lifilimi (Mochini oa ho roala oa PVC)

CLIENT: MALA WA TŠEPE(ITALY)

Automatic Laminator / PVC Coating Machine e sebelisoa haholo bakeng sa Film Lamination on Sheet Surface.E ka etsoa bakeng sa Double side Double layer Laminating.

Lamination e iketsang, ho itšeha ka ho iketsa.

* Mokhoa oa Mochine: Mofuta oa 400-2500

* Bophara bo sebetsang: 400-2500MM

* Lebelo la ho sebetsa: Lebelo le tsitsitseng / Lebelo le Fetohang

* Kopo: Mochini ona o sebelisoa haholo ho Coiler/De-coiler System,

Mochini o benyang, Mochini oa ho bentša ka seipone sa 8K, Sehiloeng ho ea ho Length Line,

Mochini oa ho sila jj.

* Mechini e ka etsoa ka mokhoa o ikhethileng.